The Moots YBB system, still in use today, came to prominence two decades ago and saw widespread use by several prominent titanium mountain bike builders. The system is simple, using a monostay configuration with a spring and/or elastomer stanchion up top and vertically compliant chainstays down low to allow for vertical movement of the rear axle. At a time when full suspension designs were often large, complex, heavy, and largely ineffective, a YBB "soft tail" could smooth much of the chatter of XC trails with relatively little fuss.

With the breakneck pace of modern suspension improvements the YBB soft tail system may seem rudimentary, but it has proven extremely durable and reliable over the years and is an integral part of many great vintage mountain bikes, most of which are still on the trails.

But all things wear out in time, and we have regularly been servicing YBB systems on Moots, Merlin, Litespeed, and other titanium bikes for many years. Generally this consists of cleaning and lubricating the parts still fit for service, or machining a new stanchion, and in the case of Litespeed modifying the Moots YBB guts that are still available to fit in the smaller diameter setup.

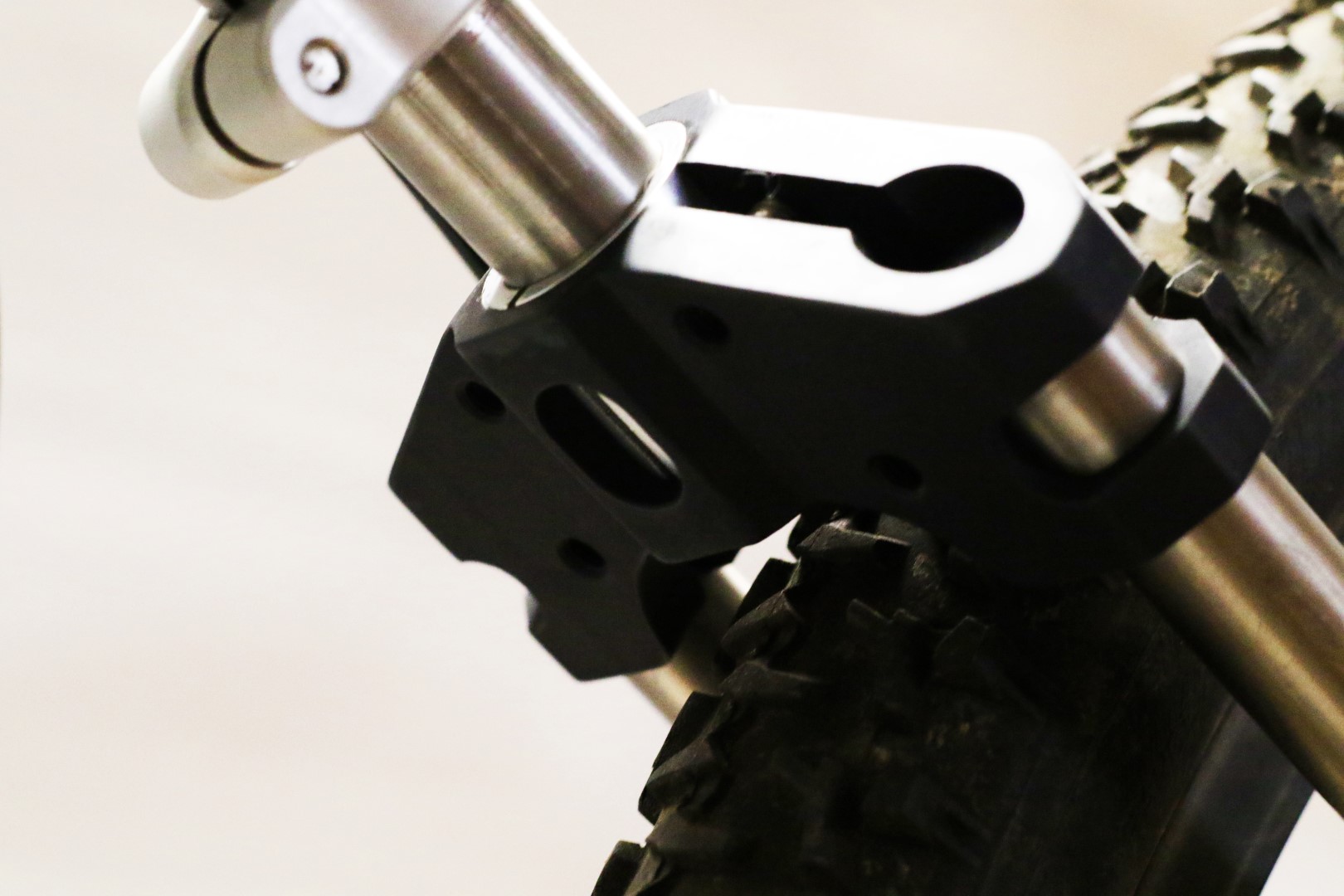

A recent Merlin project presented a different challenge; not only did the YBB guts need serviced, the aluminum bridge clamping mechanism connecting the suspension with the rear end had cracked, requiring the machining of a whole new yoke.

As far as we know this is the only Merlin Fat Beat on the planet with a black yoke, made entirely in house.